A Finnish innovation simplifies steel beam dimensioning

A customer case featuring the BeamAce device was published in the Teräsrakenne magazine: read how Ovitek Oy is already benefiting from BeamAce in their operations.

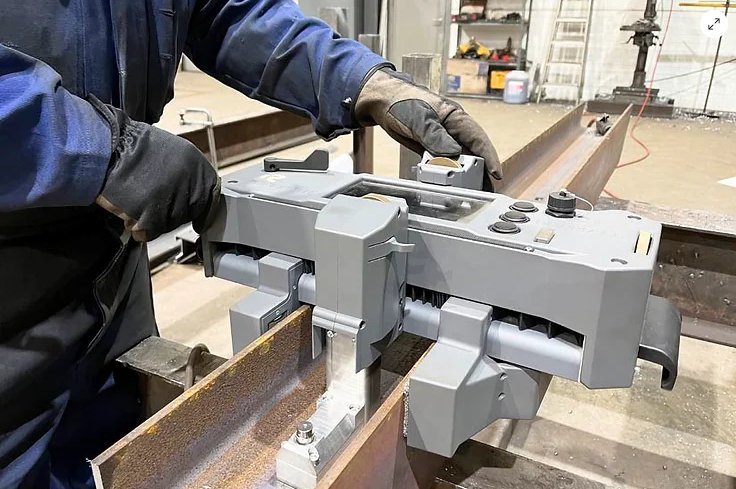

Traditional steel beam dimensioning is often slow and prone to measurement errors. The accurate, user-friendly BeamAce adds speed and reliability to the process while helping reduce costly mistakes. Traditionally, dimensioning and marking steel components has been labor-intensive and error-prone. Rockroth Oy founder Andreas Stenroth, a sheet metal welder and mechanical engineer by trade, has worked hands-on with layout marking. “From that experience within the industry, the idea gradually emerged—there’s a need for a precise, easy-to-use device that speeds up the process.”

The limitations and inaccuracy of traditional methods are especially apparent when measuring the web of a beam, and a better solution has long been needed. Stenroth began developing the device together with partners. “It was a long process because we wanted to create something that would function reliably in a workshop environment. It can be dirty and noisy there, and operators typically wear thick protective gloves—not exactly touchscreen-friendly.”

Ease of use has been the guiding principle in the product’s design. “The interface had to be as simple as possible, and the device had to be quick to learn. And that’s exactly how it turned out. After just a few minutes of introduction, users know exactly how and where to use the device.”

BeamAce was completed last year and has since generated significant interest from companies working in steel construction. According to Stenroth, the company soon entered into collaboration with Retco, a well-known player in the welding and steel structure industry. “They don’t just sell products from a catalog—they offer complete solutions.”

“Together with Retco, we’ve showcased the device at trade fairs, and there has been strong interest not only in Finland but also internationally,” Stenroth notes.

For companies that only occasionally work with steel structures, a lighter solution is also available: “BeamAce can be rented.”

BeamAce brings ease and speed to Ovitek’s daily work

Ovitek Oy is a company based in Eura, Finland, that manufactures and installs steel structures, doors, and windows. Accurate dimensioning of steel components is a central part of their daily operations. Welder Toni Systä has already tested how BeamAce performs in practice. “The icons on the machine’s screen were easy to read and quick to learn. The device itself was also simple to set up. Compared to traditional methods, its ease of use and precision were a real surprise.”

So far, two regular users at Ovitek have been working with the device. “The large and sturdy buttons make it smooth to operate. Creating a new zero point speeds up beam stair stringer dimensioning in particular,” Systä adds.

CEO Pasi Lempinen emphasizes that even at this early stage, it’s clear that BeamAce improves production efficiency. “It’s also made us think about optimizing our workflow—how one person could handle the dimensioning, just like one person handles the saw. The use of BeamAce improves accuracy and therefore reduces the risk of costly errors.”

Surprisingly positive reactions from customers

Retco Oy imports welding equipment and trains clients in the use of related tools. Product Manager Mika Talvisilta, who has 30 years of experience in the trade, knows welding tools inside and out. “BeamAce is the most impressive product innovation I’ve seen in all that time. It’s been designed from the ground up to solve the common dimensioning and layout challenges in the industry, especially with web beams.”

Talvisilta has seen firsthand how the innovation improves work. “Normally, these tasks are done with tape measures and squares, which means accuracy can vary depending on the tools and the user. BeamAce reduces layout time and, thanks to its ease of use and precision, minimizes calculation errors on the job.”

Customer feedback has been enthusiastic and even surprised. “Without exception, everyone we’ve demonstrated the device to has been amazed that such an invention was developed—and manufactured—right here in Finland,” Talvisilta shares.

Device onboarding is straightforward: Talvisilta shows one person how to use it in 15 minutes, and that person can then train their colleagues. “The easy onboarding, simple Finnish-language menus, and well-thought-out features and details have all received praise,” Talvisilta says.

Implementing a tool that simplifies work opens broader opportunities to optimize production. “Once companies get started with it, they often begin to rethink their operations. Dimensioning work may be assigned to specific individuals who handle it full-time, ensuring maximum usage and benefit from the device.”

Quality, cost-efficiency, competitiveness, and excellent customer service are key decision-making factors for many companies. Talvisilta notes that many of Retco’s clients recognize how significant the cost of dimensioning and marking is in steel structure manufacturing—as well as how expensive it is to fix layout errors. “That’s why they’ve shown such strong interest in the device.”

Translated from the original Finnish article "Suomalainen innovaatio helpottaa teräspalkkien mitoitusta".

-JP

Photos: Retco Oy

Article: Teräsrakenne 1 / 2023

Julkaistu 07.04.2025